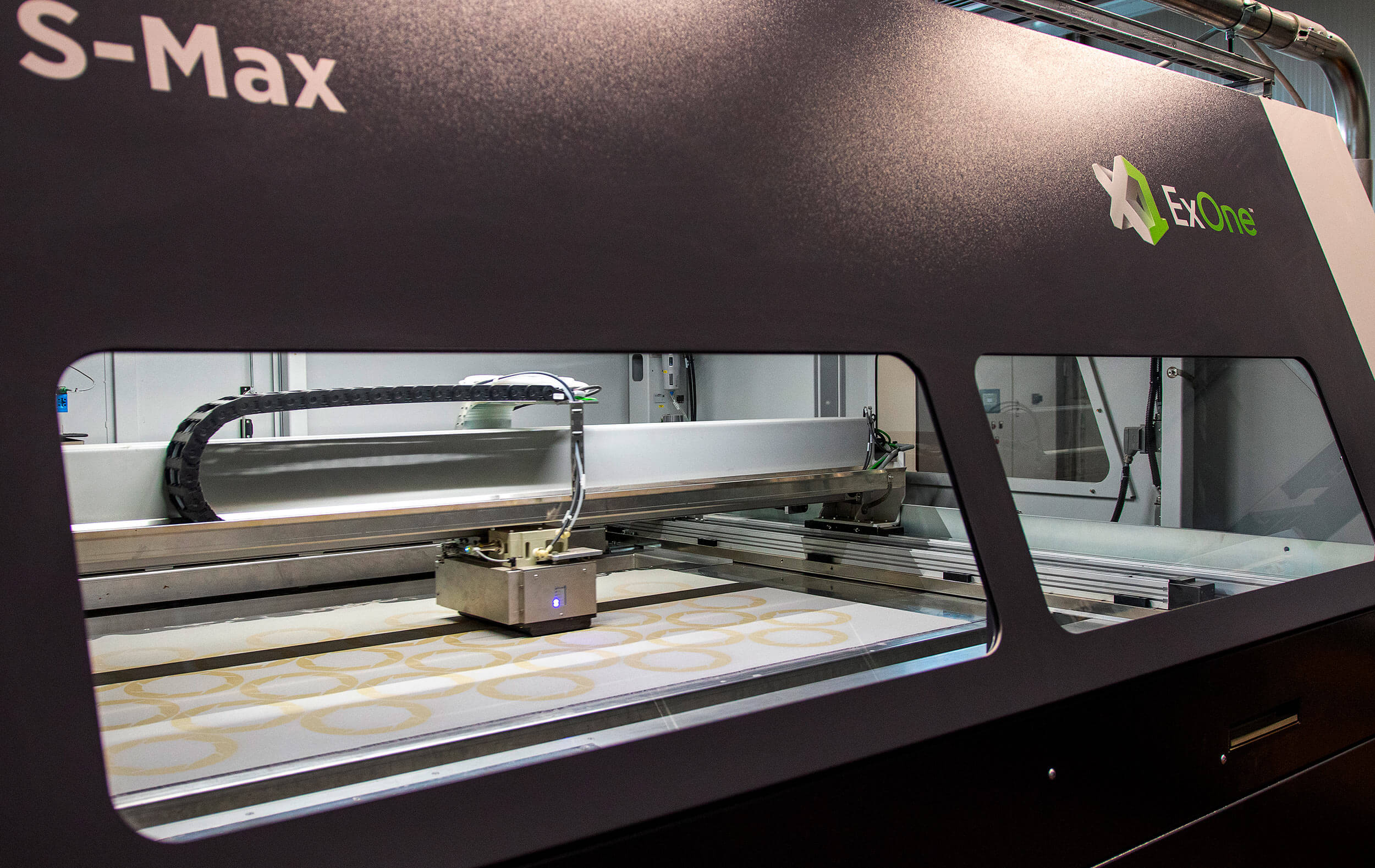

At Fonderie Palmieri, the new 3D core printing technology based on the ExOne system (Binder Jetting) is now officially operational.

A strategic investment that represents a tangible technological leap: directly from CAD files, we produce complex cores with no geometric constraints.

Layer by layer, a sand bed is selectively solidified using a chemical binder, allowing perfectly formed cores—ready for pouring—to be produced in just a few hours, including internal geometries that were previously impossible to achieve.

For our customers, this means:

– complete design freedom

– rapid prototyping and pre-series production

– reduced time-to-market

– elimination of complex core assemblies.

3D printing applied to core manufacturing improves not only flexibility, but also casting quality, thanks to a finer and more controlled surface finish.

A concrete bridge between foundry tradition and process digitalization, positioning Fonderie Palmieri among the most advanced foundries in Italy.