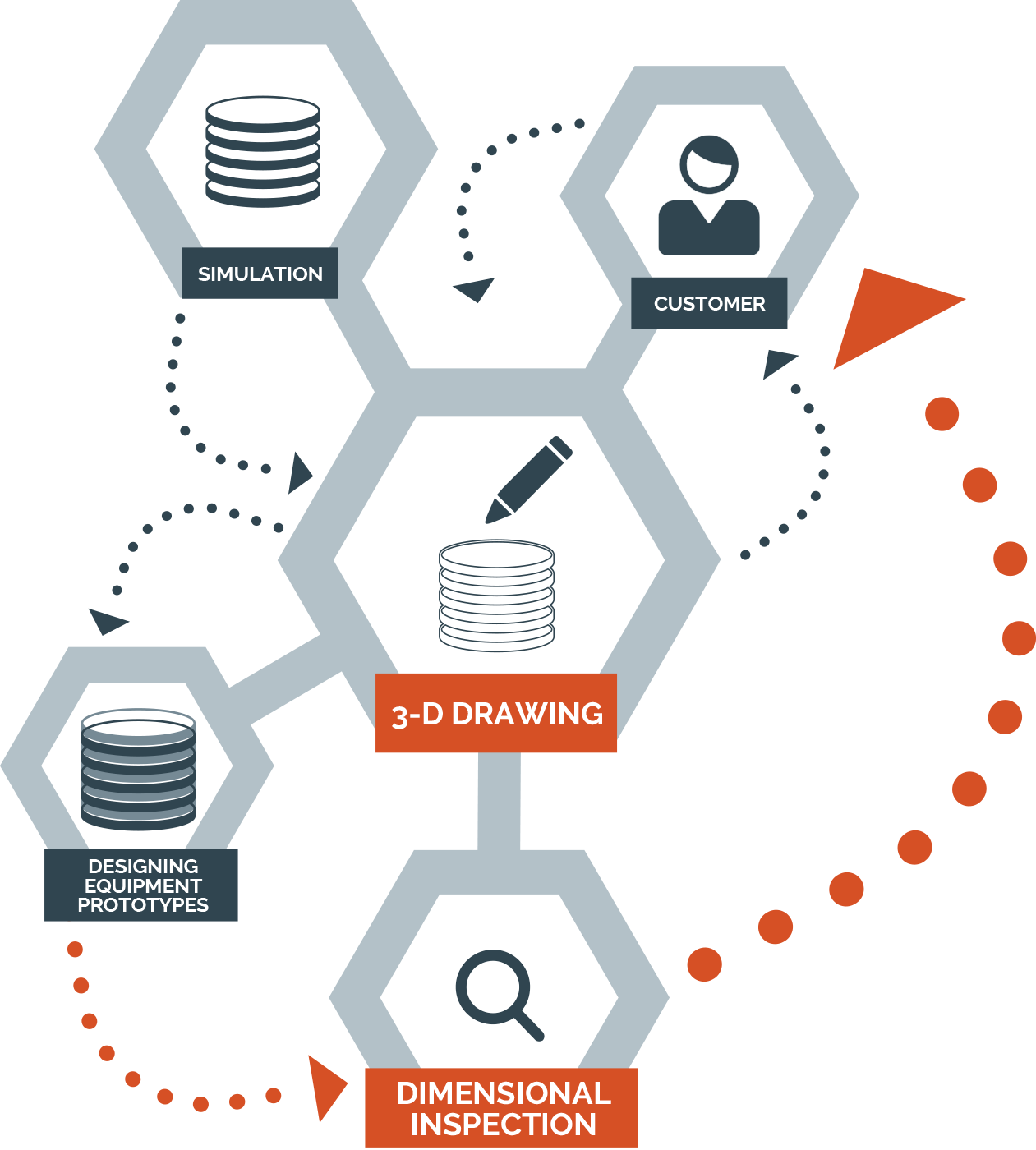

The support of 3D technologies facilitates the exchange of information during the design stage.

The same mathematics will be used to carry out various simulations guaranteeing the greatest reliability in the analysis of the difficulties related to the casting.

3D technology facilitates the core pulls, the creation of the plates to generate the model and an esteem of the shrinkage. After the design, three-dimensional drawings are directly used by the means of CAD/CAM for the construction of equipment.

Lately, the original drawings can be used as input data for the dimensional control of the product. A point cloud of the sample is generated using an optical scan device: this will be compared to the original drawing data and possible differences would be showed as 3D deviations.